Subaru Forester SG: Charge Speed Style Bonnet Scoop (2002-2008)

$340.00

LOCAL PICKUP AVAILABLE:

56 Rosedale Street

Coopers Plains QLD 4108

Monday - Friday 9am - 4:30pm

Quick Summary: Transform your Subaru Forester SG with this premium Charge Speed Style Add-On Bonnet Scoop. Handcrafted in Brisbane using Hand Laid FRP, it is engineered for both daily drivers and performance builds. This heat-resistant, rust-proof panel is manufactured to order at our Coopers Plains workshop with a 2-week lead time.

SUBARU FORESTER SG CHARGE SPEED STYLE BONNET SCOOP (2002-2008)

Renew the look of your ride and transform the front profile of your Subaru Forester SG. Manufactured by Monkey Warehouse in Brisbane, this component is engineered using premium FRP Hand Laid techniques. This provides a high-strength, lightweight alternative to standard factory components that maintains its structural rigidity even when exposed to high engine bay temperatures.

| TECHNICAL DATA SHEET | |

|---|---|

| Construction | Premium Hand Laid FRP |

| Origin | 100% Australian Made (Brisbane Workshop) |

| Finish | Raw Gel Coat (Raw / Unpainted) |

| Included Components | 1 x Charge Speed Style Add-on Bonnet Scoop |

| Benefits | Rust-Proof, Heat-Resistant and Fully Repairable |

COMPATIBILITY

To ensure you are ordering the correct part for your build, please verify your vehicle details:

- Vehicle: Subaru Forester SG (Second Generation)

- Body Style: Wagon

- Year Range: 2002, 2003, 2004, 2005, 2006, 2007, 2008

- Fitment Note: Specifically designed to fit 100% on a flat factory bonnet.

THE MONKEY WAREHOUSE ADVANTAGE

- 20 Years of Composite Heritage: Hand-crafted by experts with two decades of experience in the Australian automotive aero industry.

- 100% Brisbane Made: Proudly manufactured at our Coopers Plains workshop. Thank you for supporting Australian manufacturing!

- Hand Laid Structural Integrity: Unlike cheap chopper gun imports, our Hand Laid process ensures consistent panel thickness and a superior strength-to-weight ratio.

- Heat-Resistant Durability: FRP is 100% rust-proof. As a "thermoset" material, it maintains its rigid shape under the Australian sun and engine bay heat, resisting the warping common in plastic parts.

- Serviceable Design: Engineered to be a "serviceable" part: if damaged, it can be professionally re-glassed rather than replaced.

SHIPPING AND LOCAL PICKUP (BRISBANE)

To get the most competitive freight rates, shipping is calculated based on your specific location.

- Add the scoop to your cart and proceed to the View Cart / Checkout page.

- Use the Shipping Calculator by entering your postcode. This will determine your freight rate or enable the 'Pick-up from Store' option at our Coopers Plains workshop.

- If a rate is not automatically available, select 'Create Quote from Cart', and our team will provide a manual quote within 1 to 2 business days.

ORDERING AND MANUFACTURING TIME

This product is Made to Order to ensure strict quality control.

- Lead Time: Approximately 2 weeks for manufacturing. If completed earlier, it will be dispatched immediately.

- Urgent Orders: Please contact us via email before ordering if you have an upcoming show or project deadline.

INSTALLATION AND FITMENT EXPECTATIONS

This is a high-quality aftermarket FRP product. For a professional finish, the following workflow is required:

- Pre-fitting: Always test-fit the part to the vehicle "dry" before any modification, sanding, or painting.

- Professional Adjustment: Minor sanding, trimming, or heat application may be required to achieve your desired alignment. This is standard for custom composite aero parts.

- Preparation: Requires professional sanding and priming before painting to match your vehicle paint code.

- Expert Fitment: We strongly recommend installation by a qualified body shop experienced in FRP products to ensure a professional finish.

FREQUENTLY ASKED QUESTIONS

Is FRP suitable for a Subaru daily driver?

Absolutely. FRP is ideal for daily use because it is 100% rust-proof and heat-resistant, meaning it won't sag or warp in the extreme temperatures of an Australian engine bay.

What happens if I damage it?

This is the primary advantage of Hand Laid FRP. Unlike plastic parts that are often "disposable" once cracked, FRP is fully repairable. It can be ground back and re-glassed by a professional.

What is the difference between Hand Laid and Chopper Gun?

Chopper guns spray random glass strands, leading to brittle sections. Our Hand Laid process manually layers glass mats, ensuring a better resin-to-glass ratio and higher impact resistance.

Does it come painted?

No. It arrives in a raw gel-coat finish. It requires standard preparation, priming, and painting by a professional to match your vehicle perfectly.

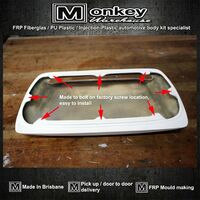

Why is there a modified bottom insert?

We have engineered a modified bottom insert panel specifically to assist with structural mounting and alignment, making the installation process more straightforward.

RESOURCES AND BUILD SUPPORT

As a Brisbane-based manufacturer, we believe in transparency. Learn more about the technical standards we uphold at our Coopers Plains workshop:

- Technical Deep Dive: What is Hand-Laid FRP?

- Material Comparison: The Ultimate Australian Guide to Body Kit Materials